Batch Score - Quality Assurance

As previously described, the BeerBotz system records the temperature and CO2 during a batch. To

create the "Batch Score" after a fermentation has been completed, the Excel™ spreadsheet is queried for

two values:

- Gas start time (when first noticeable gas comes out) aka: lag time

- Time to peak CO2 gas flow rate

These two values can be determined unambiguously from the batch spreadsheet data. The values for each batch

contribute to building a "Batch Score" graph. All of the previous batches are represented on this

graph. This allows you to see your average batch performance and, most importantly, spot a batch that

has performed below average. A poor performer probably had problems with the yeast that was used. The

Batch Score can be used to monitor the quality of your yeast!

Adding a yeast pitch to the unfermented wort sugars is a little like throwing a match on a pile of

gun powder. Once the reaction starts it creates a bunch of gas. The difference is that, with beer

fermentations, the speed of the reaction can be tempered/slowed by lowering the wort temperature.

For all fermentations, there is a beginning (first noticeable gas) and a peak gas flow. Since the entire

reaction is slowed by making the wort colder the expectation is that, on average, these values would

change with the temperature that the wort is kept at.

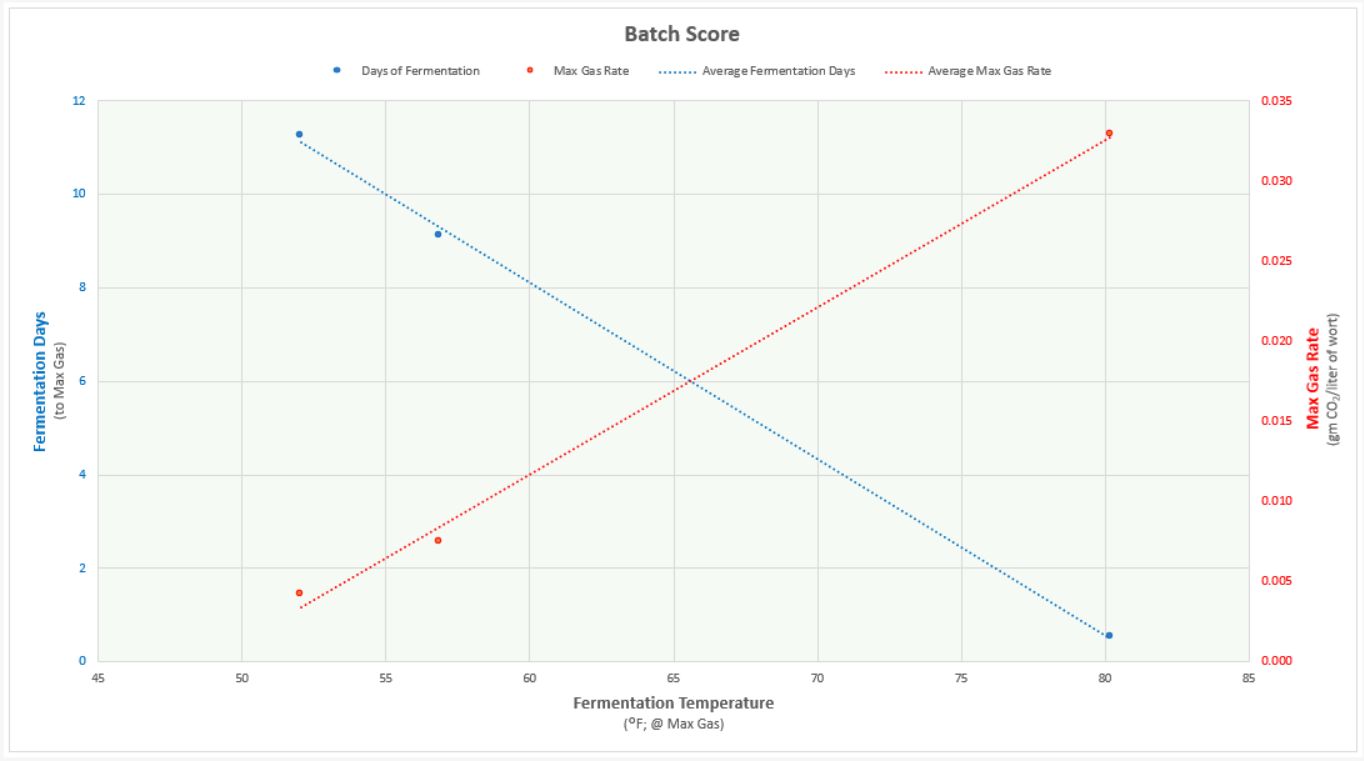

In the Batch Score graph above, the temperature is the main x axis. This is because the expectations for

the performance rates of the batch depends primarily on temperature. The blue/left y axis is the

fermentation time (gets longer for colder wort). The red/right y axis is the actual observed peak gas

measurement (higher/more gas for warmer wort).

Each batch shows an entry for fermentation time and peak gas rate (the dots). The lines are linear

trendlines that are automatically generated by Excel™ from the batch data. These lines are the average

expectation for the performance of a batch in your operation at the given temperature. Since these

trendlines are automatically generated they will get more precise as more data points/batches

are added. Let's look further at where a batch reading (dot) can appear on the graph and what that

means.

Fermentation Days

Fermentation Days

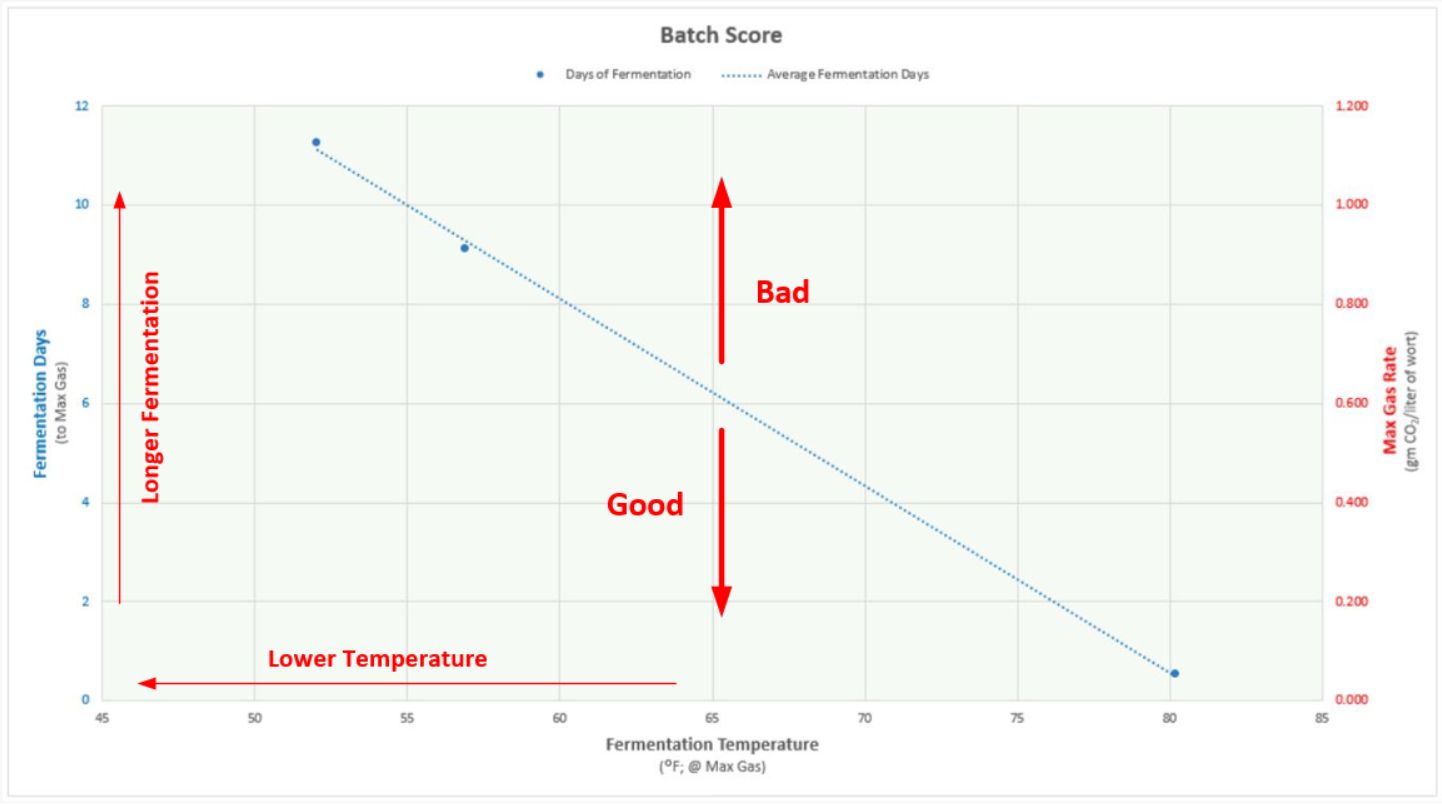

Fermentation Days (length of fermentation) is on the left y axis. The higher the value, the longer the

fermentation took. Notice that, from the average line, the lower the temperature (x axis), the longer

the expected fermentation time.

Now, say you have just placed the data in the Batch Score graph, and you see the data point is higher than

the average line. That means that your last batch has taken longer than normal for a given batch...

which is bad. There was a problem with the yeast pitch.

If the data point appears below the average line (or on the line), it just indicates normal operations

(all is well!).

Maximum Gas Rate

Maximum Gas Rate

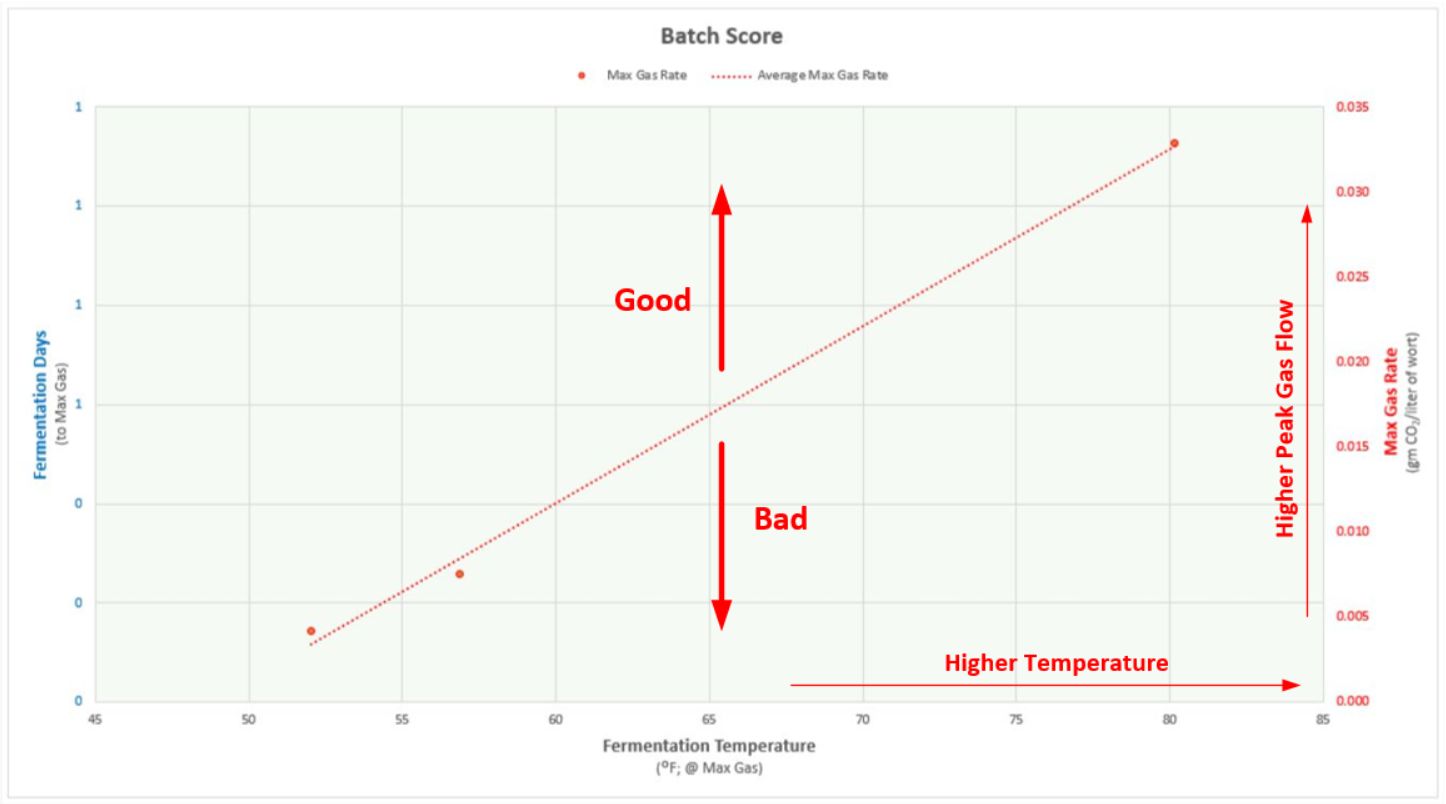

Maximum Gas Rate (peak CO2 flow) is on the right y axis. The higher the value, the greater

amount of gas was produced from an individual meter reading. This is the "explosive force" for this

batch (to continue the gun powder analogy). From the average line you can see that, as the

temperature increases, the expected peak gas flow increases (bigger boom!).

Now, say you have just placed the data in the Batch Score graph, and you see the data point is higher than

the average line (or on the line). That means that your last batch had a peak gas flow rate higher than/or

equal to the expected rate for a given batch. No problems here... move along!

If the data point appears below the average line then the peak gas flow was lower than normal. There was a problem

with the vigor of the yeast... they did not "push" with the expected force.

That is the Batch Score graph! It allows you to compare the performance of all of your previous batches in

one view. It helps you to accumulate your organizational knowledge and identify potential process

improvements. Next, take a look at how these two values (Gas Start & Max Gas) are acquired from the

raw batch data spreadsheets: Batch Score Instructions.